Internet of Things (IoT) has become a buzz-word as the global industry is migrating towards centralized corroborative strategizing. Modern industries demand real-time monitoring and decision making for processes, inventories and operations. This requires sensing of parameters and communication to the concerned global locations over the internet. This is known as the 4th revolution in industries or ‘Industry 4.0’. Being technologically up to date by compliance to Industry 4.0 standards is soon becoming a necessity for operating in the rapidly changing and extremely competitive industrial segment.

In spite of the presence of global players in IoT & IIoT infrastructure, the domain of ‘last mile interfacing’ is still empty. The demand of interfacing connected electronics to industrial processes is still an ill-addressed necessity. AGV has a wide range of products that bridge this gap. Our modular products are configurable to almost every system and process in the industry. In other words, AGV’s IoT solutions provide a seamless membership to the ‘Industry 4.0’ club.

-&-Industry.jpg)

AGV’s Furnace Monitoring System provides a user-friendly solution to monitoring the temperatures, pressures, humidity, gassing and energy consumption of industrial furnaces and facilitating control action at appropriate time. This has led to energy efficient operation, added traceability and avoided production defects and rejections in industries.

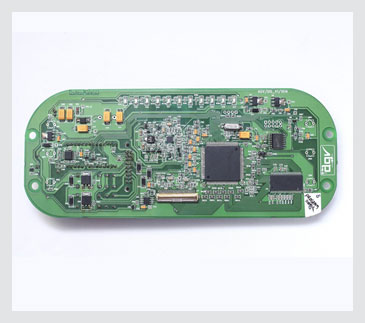

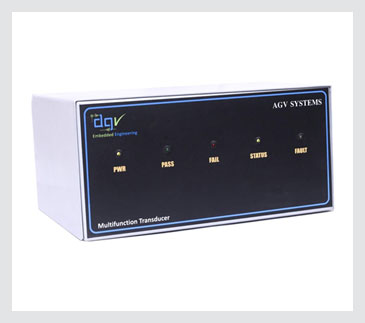

AGV’s Refrigerator Parameter Monitoring System is designed to test the cooling and safety performance of refrigerators right on the assembly / production line thereby automating recording of all the Quality Checkpoints of the refrigerator. Various models of refrigerators can be tested simultaneously. The current, voltage and temperature curves are analysed by the system online. The Pass/Fail decision making is independent of an operator.

The Refrigerator Parameter Monitoring System eliminates the human error while making Quality measurements, speeds up the QC process and saves a significant amount of cost due to the reduced testing time.

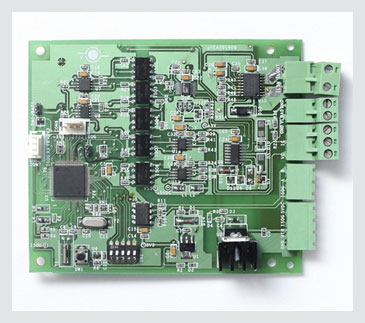

It is well established that ‘supervisory monitoring and control (SCADA)’ system is a need for resource optimal operations of industrial processes. In today’s having just a SCADA system is no longer sufficient and conventional SCADA now needs a decision making and controlling capability on the edge. Yet many Micro and Small Enterprises haven’t even moved to SCADA till date. The physical boundary of conventional wired SCADA systems is extended by AGV’s ‘Remote Parameter Monitoring System’. This system also provides remote control action; thus making it an IIoT avatar of SCADA. In many situations, even the absence of a proper SCADA system can be compensated by AGV’s Remote Parameter Monitoring Systems.

Industrial assembly lines and multi-function shop floors often face the challenge of monitoring and maintaining production machinery as well as scheduling and tracking actual production status for batch processes. Due to a mix of current generation and legacy machinery, it is often tricky to collect the relevant data from all points of action. In such cases, AGV offers customized solutions for enabling IIoT on industrial shop floors by using various sensors and gathering real-time data directly from the processes. This solution is generally configured using a combination of technologies like Zig-bee, Wi-Fi, Ethernet, RS485 etc.

This solution enables key personnel possible to have an instantaneous detailed status of the shopfloor, the machines, the downtime, the data on scheduled as well as unscheduled maintenance, the overall productivity, and the production efficiency available on their fingertips.